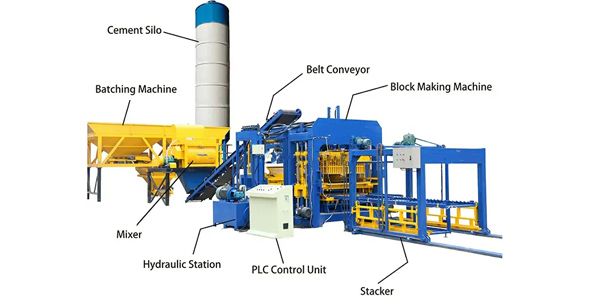

QT8-15 Concrete Block Machine is multifunctional. By changing molds, it can produce a variety of concrete block products. Compared to the QT6-15 model, the output and production efficiency are significantly improved.

01 Technical Specifications of QT8-15 Block Machine

Back

Overall Dimension

8300x1860x3000mm

Rated pressure

21MPa

Main vibration form

Platform vibration

Cycle Time

15-25 seconds

Vibrating Frequency

2800-4500 rolls/minute

Pallet Size

950x900mm

Motors Power

55.5kw

Weight

9700kg

02 Advantages of QT8-15 Block Making Machine

Back| ENLARGE THE VIBRATING BOX The vibrating source is uniform and stronger. |

|

|

SIEMENS PLC International brand, long service life, basically not damaged. |

| 4 SIEMENS VIBRATION MOTORS fast start, high frequency, strong vibration force, make good brick quality. |

|

|

SCHNEIDER, OMRON ELECTRICAL DEVICES Interval pressure supply, each action is fast and smooth. |

| JAPAN YUKEN HYDRAULIC VALVE / PROPORTIONAL VALVE Fast response, long life.. |

|

|

MATERIAL FEEDER V-shaped feeding tooth, uniform feeding, 0 failure rate. |

| MATERIAL HOPPER Adopt endless belt, uniform, more accurate discharge volume. |

|

|

GUARD NET Ensure the safety of workers, good-looking appearance. |

03 QT8-15 Production Capacity

Back| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block | 400x200x200 | 15-20 | 8 |

1440-1920 |

11520-15360 | |

| Hollow block | 400x150x200 | 15-20 | 12 |

2160-2880 |

17280-23040 |

|

| Solid block | 240x110x70 | 15-17 | 33 |

6988-7920 |

55904-63360 |

|

| Paver | 225×112.5×60 | 15-25 | 21 |

3000-3780 |

24000-30240 |

|

| Paver | 200x100x60 | 15-25 | 32 |

4600-7680 |

36800-61440 |

04 Why Choose the QT8-15 Block Machine?

Back✅ High Efficiency and Stability: The automated control system improves production efficiency and ensures stable long-term operation, reducing downtime.

✅ Versatility and Strong Adaptability: Capable of producing various types of bricks, meeting different market demands, and ideal for small to medium-sized enterprises.

✅ Energy-Saving and Environmentally Friendly: Utilizes energy-efficient technology to reduce energy consumption and environmental impact, meeting modern environmental standards.

✅ Cost-Effective: The machine is reasonably priced, with high automation, helping to reduce labor costs and improve production efficiency.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com