Advantages of the Brick Making Machine Industry in Solid Waste Treatment

queenbrick

queenbrick

May 31, 2025

May 31, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

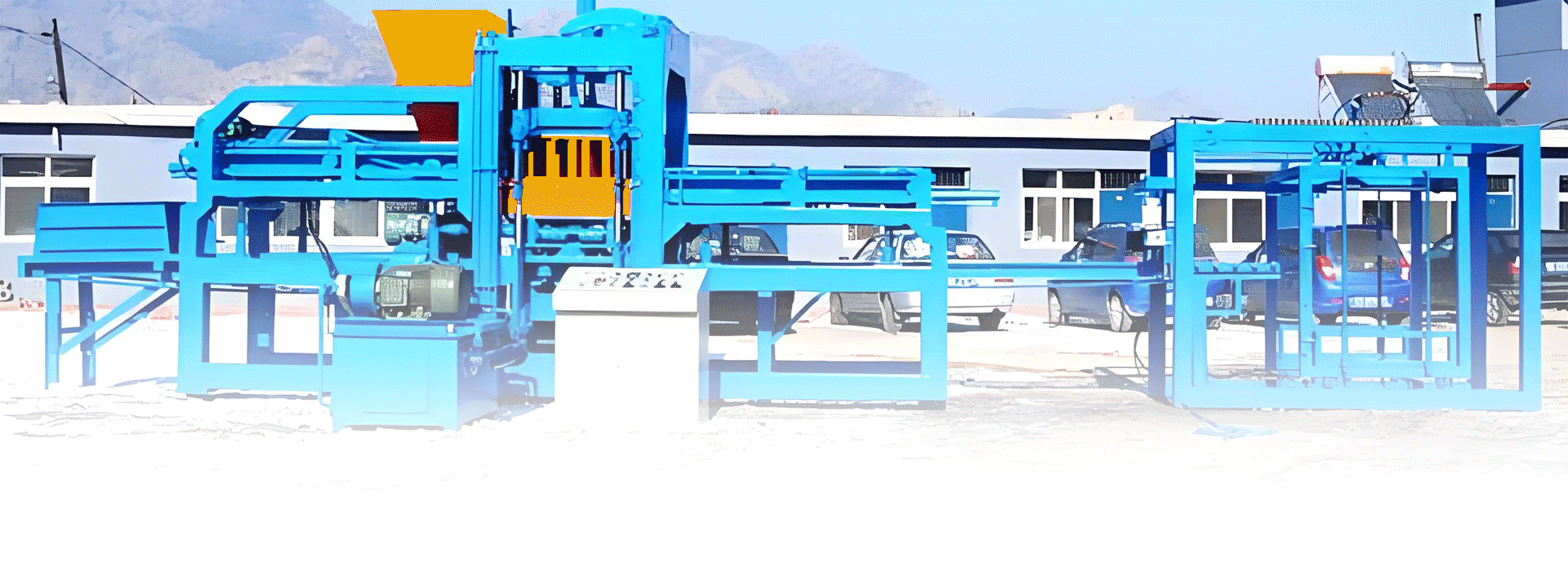

With the rise of sustainable development and the growing urgency to manage industrial and construction waste, brick making machines are emerging as a powerful solution for solid waste recycling. These machines not only help protect the environment but also offer substantial economic and technological benefits. Here are the key advantages:

01Significant Environmental Benefits

BackResource Reuse

Brick making machines can convert various types of solid waste—such as industrial by-products, construction debris, and mining tailings—into valuable building materials. This greatly reduces dependence on natural clay and other non-renewable resources.

Pollution Reduction

By eliminating the need for high-temperature firing (as in traditional clay brick production), solid waste brick making significantly lowers emissions. It also helps minimize land occupation by reducing the volume of waste dumped in landfills or left in storage piles.

02Outstanding Economic Benefits

BackLow Input Cost, High Output Value

Solid waste materials are inexpensive or even free in many cases, and the bricks produced have high added value. This creates a highly profitable business model for brick manufacturers.

Product Diversification

With the ability to switch molds, a single brick making machine can produce a variety of products—including standard bricks, hollow blocks, curbstones, and imitation stone bricks—enabling businesses to meet diverse market demands and expand their product offerings.

03Advanced Technology and Automation

BackFully Automated Production

Modern automatic brick making machines streamline the entire production process—from raw material feeding to final product output. This reduces labor costs and boosts productivity.

Intelligent Control Systems

Features like automated batching, precision pressing, palletizing, and packing ensure high product consistency and minimize human error. Intelligent monitoring systems also improve operational stability and reduce downtime.

04Broad Market Prospects

BackGrowing Demand for Green Building Materials

As cities push for eco-friendly urban development, there’s a rising need for environmental bricks made from recycled materials. These products are widely used in urban renewal, sponge city projects, infrastructure, and landscaping, offering strong and sustained market potential.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now