Features and Types of New Automatic Brick Making Machines

queenbrick

queenbrick

May 31, 2025

May 31, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

With growing environmental awareness and the need for sustainable urban development, the brick-making industry is undergoing a significant transformation. Traditional clay brick production—though still in use—poses serious concerns, such as land degradation and environmental pollution. In contrast, modern automatic brick making machines are designed to produce eco-friendly bricks using industrial waste materials like fly ash, slag, and construction debris. These green bricks not only conserve land resources but also promote the reuse of waste, aligning perfectly with the goals of sustainable construction.

01Eco-Friendly Materials for a Greener Future

BackToday’s automatic brick machines support the production of environmental bricks, a new generation of wall materials designed to replace clay bricks. These bricks utilize waste materials and reduce the environmental footprint of construction projects. Their increasing popularity highlights a shift toward green building materials that are both resource-efficient and cost-effective.

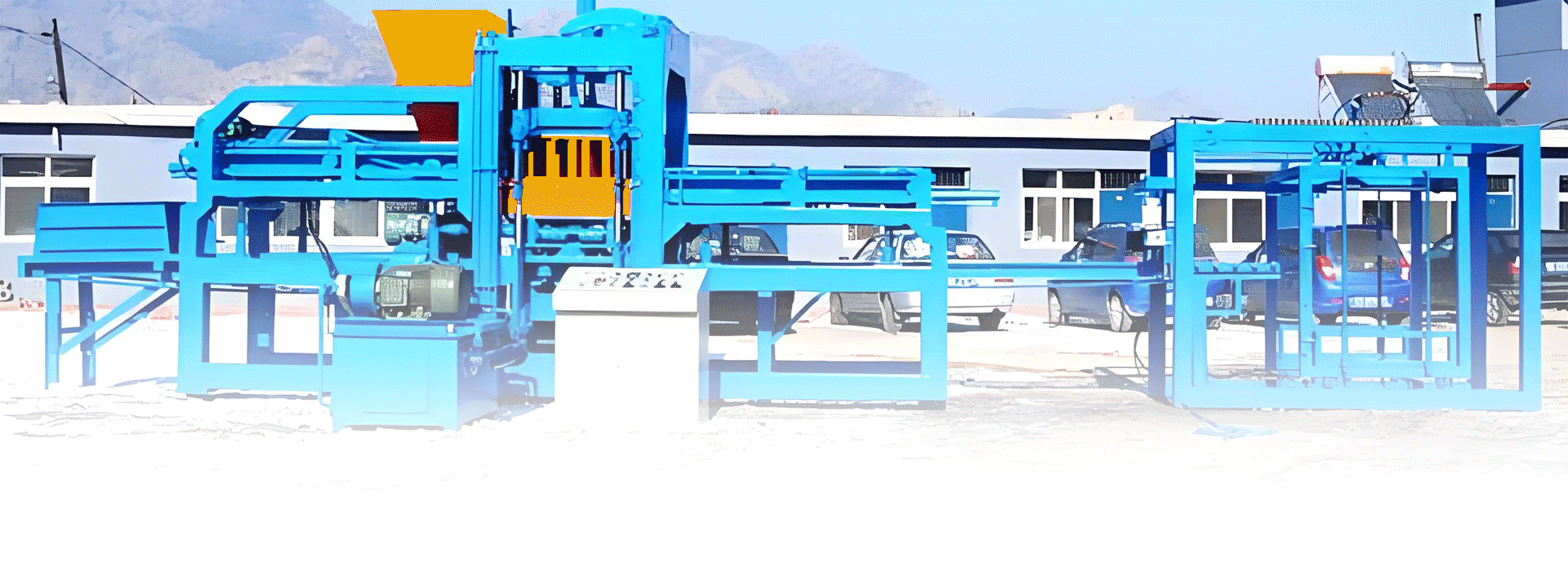

02Types of Automatic Brick Making Machines

BackCurrently, there are two main structural types of automatic brick machines:

1. Four-Column Hydraulic Brick Making Machine

This traditional model features a three-beam four-column structure and uses a hydraulic system to apply pressure during molding. While it improves production efficiency, it comes with notable drawbacks:

Higher failure rate due to aging seals and components in dusty brick factory environments.

Uneven density in bricks, especially where the upper and lower molds meet, due to direct pressure and limited material flow.

Quality issues, such as cracked or defective corners, caused by poor fluidity and friction during pressing.

2. Eccentric Vibration Brick Making Machine

This newer model utilizes eccentric vibration technology rather than direct hydraulic pressure. Vibration helps the raw materials settle evenly in the mold, improving:

Brick density and uniformity

Production speed

Overall product quality

Additionally, the lower reliance on hydraulic systems reduces wear and maintenance requirements, making it a more reliable and efficient choice for modern brick manufacturing.

Conclusion

As the demand for sustainable construction materials grows, automatic brick making machines must evolve to meet higher standards of efficiency, quality, and environmental responsibility. Machines that produce green bricks using fly ash and other recycled materials are leading the way, while newer vibration-based technologies offer better durability and product consistency. When choosing a brick machine, understanding the differences between hydraulic and vibration types is key to making the right investment for long-term productivity and sustainability.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now