High-Efficiency Brick Making Machines for Sale

queenbrick

queenbrick

August 27, 2025

August 27, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Brick making machines have become the cornerstone of modern construction, revolutionizing the way building materials are produced. With their high efficiency, versatility, and environmentally friendly design, these machines are indispensable in today’s construction industry. They not only save time and labor but also play a vital role in infrastructure development, real estate projects, agricultural modernization, and sustainable building practices.

01How Brick Making Machines Work?

BackThe working principle of a brick making machine is both simple and effective. It compresses a mixture of soil, water, and other raw materials into molds, forming bricks of various shapes and sizes.

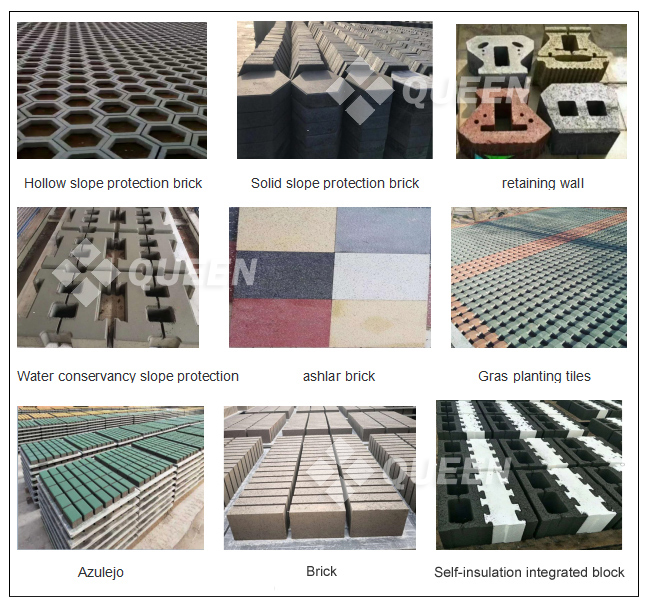

It can produce:

Standard bricks

Pavement bricks

Hollow bricks

Curb stones

Grass-planting bricks

PC imitation stone bricks

This versatility ensures that builders can meet the diverse requirements of different construction projects with ease.

02Wide Applications of Brick Making Machines

Back1. Infrastructure Development

Bricks produced by these machines are widely used in roads, railways, bridges, and tunnels. Their reliability under different environmental conditions provides a strong foundation for large-scale infrastructure projects.

2. Real Estate Construction

As real estate continues to grow, so does the demand for high-quality bricks. Brick making machines supply residential, commercial, and industrial projects with durable building materials, ensuring construction efficiency and quality.

3. Agriculture

From irrigation projects to greenhouses and livestock facilities, machine-made bricks support agricultural modernization. They are cost-effective and reliable, providing sustainable solutions for farming infrastructure.

4. Environmental Protection

Some brick making machines can recycle waste materials such as concrete, sludge, or construction debris into eco-friendly bricks. This reduces environmental pollution, promotes resource reuse, and contributes to green building initiatives.

5. Urban Landscaping and Defense Construction

Machine-made bricks are also used in urban landscaping, parks, parking lots, and military facilities such as barracks, airfields, and defense installations. These applications further expand the market potential of brick making machines.

03Future Trends of Brick Making Machines

BackWith continuous technological advancements, brick making machines are moving toward intelligent, eco-friendly, and highly efficient designs.

Future brick making machines will:

1. Adapt to multiple raw materials and brick types

2. Consume less energy and produce minimal pollution

3. Support sustainable construction practices globally

04Why Choose a Brick Making Machine?

BackInvesting in a high-quality brick making machine ensures:

Faster production and lower labor costs

Consistent brick quality

Flexibility for various construction projects

Contribution to eco-friendly building practices

Whether you are a developer, contractor, or agriculture facility manager, choosing the right brick making machine can significantly improve efficiency and reduce operational costs.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now