How do main chemical components in raw materials affect brick making?

queenbrick

queenbrick

June 4, 2025

June 4, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

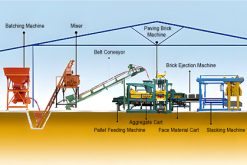

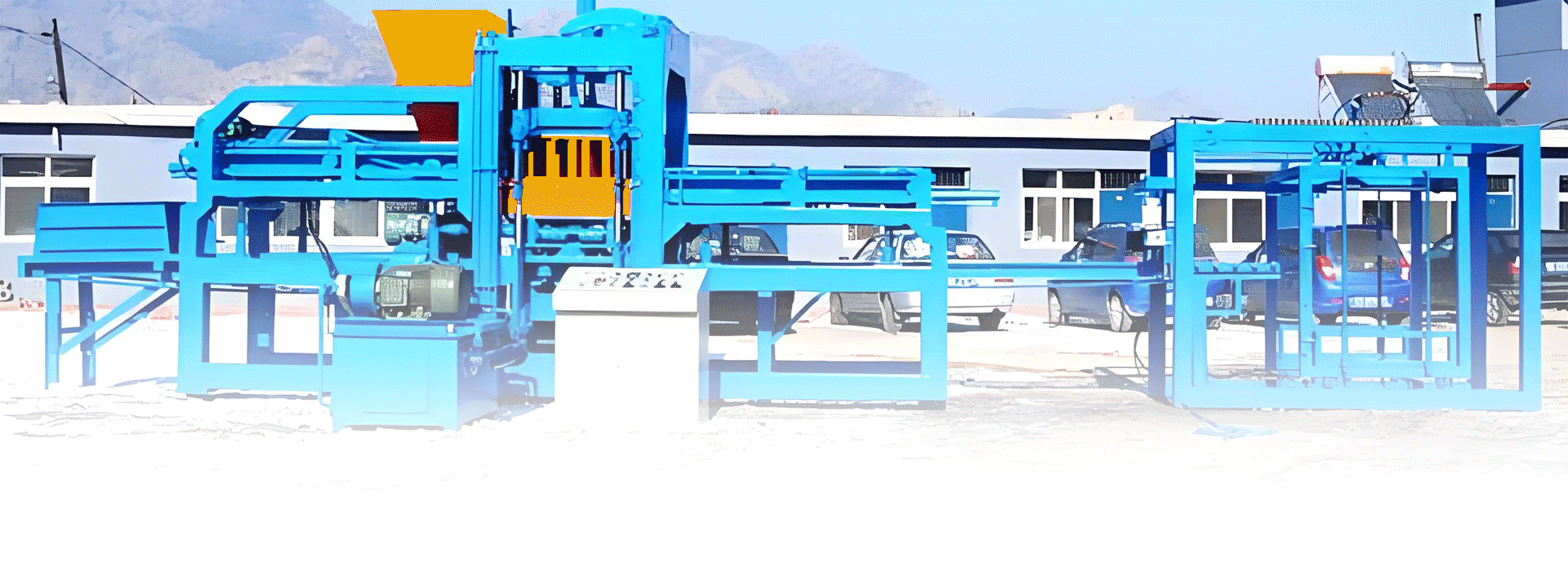

The quality and performance of bricks produced by a brick making machine are significantly influenced by the chemical composition of the raw materials used. Understanding the role of each chemical component helps ensure optimal molding, firing, and final product quality. Below is a breakdown of the key chemical components and their impact on brick making:

1. Silicon Dioxide (SiO₂)

Ideal Content: 55% – 70%

Function: Main structural component in sintered brick raw materials.

Effect:

Provides hardness and strength.

Excess content reduces plasticity, making molding difficult.

Can lead to firing expansion and reduced product strength.

2. Aluminum Oxide (Al₂O₃)

Ideal Content: 10% – 25%

Function: Contributes to the plasticity and bonding ability of the clay.

Effect:

Too little results in low strength and poor durability.

Too much raises firing temperature, increases fuel consumption, and produces a pale brick color.

3. Iron Oxide (Fe₂O₃)

Ideal Content: 3% – 10%

Function: Acts as a coloring agent and flux.

Effect:

Enhances brick color (reddish tone).

Excessive amounts reduce the refractoriness of the bricks, making them more prone to deformation under high heat.

4. Calcium Oxide (CaO)

Ideal Content: Less than 5%

Function: Often present as limestone (CaCO₃); considered a harmful impurity.

Effect:

Narrow sintering range, complicates the firing process.

Large particles (>2 mm) cause lime bursting, leading to cracking or disintegration.

Can absorb moisture post-firing, resulting in brick weakening.

5. Magnesium Oxide (MgO)

Ideal Content: Less than 3%

Function: Typically considered a harmful impurity.

Effect:

Contributes to efflorescence (white salt deposits) when combined with sulfates.

Can cause peeling or weathering of the finished brick.

6. Sulfur Trioxide (SO₃)

Ideal Content: Preferably 0%, but should not exceed 1%

Function: Impurity, often present in industrial by-products or contaminated raw materials.

Effect:

Decomposes during firing, releasing gases that cause expansion and cracking.

Leads to structural failure or disintegration of bricks.

Conclusion

The chemical makeup of brick making raw materials plays a critical role in determining the quality, durability, and appearance of the final product. Proper testing and control of these components help avoid defects such as low strength, color fading, deformation, cracking, and weathering.

For manufacturers using brick making machines, careful selection and preparation of raw materials are essential steps to ensure efficient production and high-performance bricks.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now