How to Choose Between Diesel and Electric Concrete Mixers with Pumps?

queenbrick

queenbrick

October 17, 2025

October 17, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

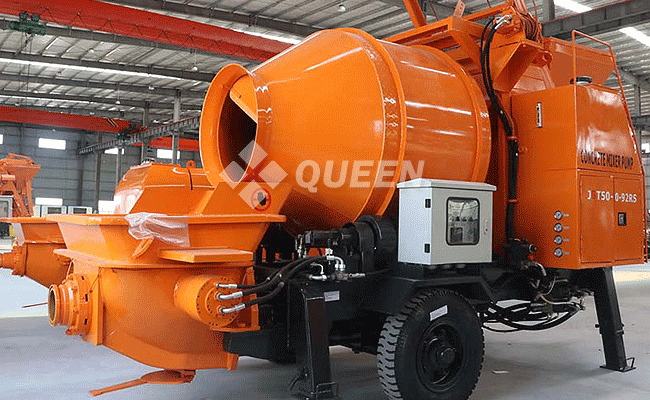

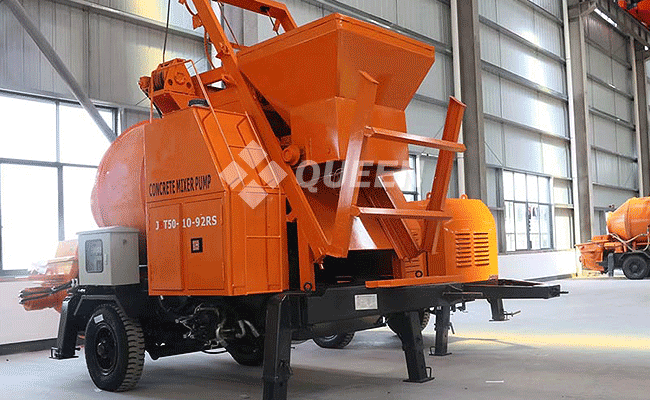

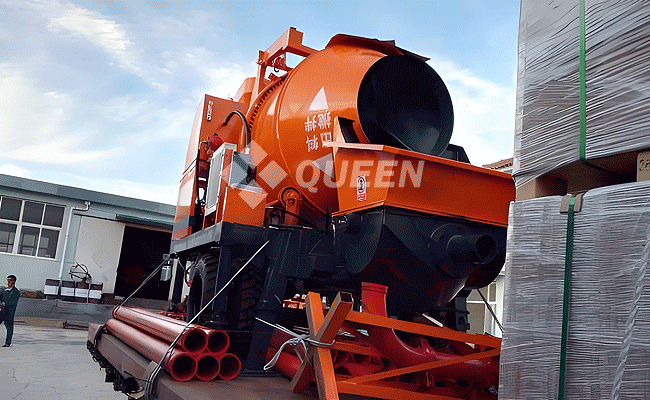

When selecting a concrete mixer with pump, choosing between a diesel and electric model is essential. Both options have specific advantages depending on your project’s needs. Here’s a breakdown of the key factors to consider when making your decision.

01Power Source & Location

BackDiesel Concrete Mixers with Pumps: These are ideal for remote construction sites or locations with unreliable electricity. Diesel-powered mixers are highly flexible and can handle large-scale operations without the need for an external power source.

Electric Concrete Mixers with Pumps: Best suited for projects located in areas with reliable electricity. They are energy-efficient, produce less noise, and have minimal environmental impact, making them perfect for urban or residential construction projects.

02Operational & Maintenance Costs

BackDiesel Mixers: The operational costs for diesel-powered mixers are higher due to fuel consumption, and they require regular maintenance such as engine and fuel system checks. However, they are designed to handle heavy-duty work.

Electric Mixers: Electric concrete mixers with pumps typically have lower operational costs, as electricity is more affordable than diesel. These mixers require less maintenance due to fewer moving parts and are easier to maintain overall, making them more cost-effective in the long run.

03Noise & Environmental Impact

BackDiesel Mixers: Diesel mixers tend to be noisier and produce exhaust emissions, which can be problematic in urban or environmentally sensitive areas. They are generally not suited for projects with strict noise control regulations.

Electric Mixers: Electric mixers operate with minimal noise and produce zero emissions, making them more environmentally friendly. These mixers are perfect for projects that prioritize eco-friendliness and noise reduction.

04Mobility & Flexibility

BackDiesel Concrete Mixers with Pumps: These mixers are more mobile and can be used in areas without access to electrical power. They are perfect for large projects in remote locations or places lacking electrical infrastructure.

Electric Concrete Mixers with Pumps: While electric mixers are less mobile due to their dependence on power sources, they work best in urban construction sites where electricity is readily available and stable.

05Conclusion

BackChoose a diesel concrete mixer with pump for remote sites, high mobility, and more power requirements. Opt for an electric concrete mixer with pump when you have access to reliable electricity, want lower operating costs, and need a quieter, environmentally friendly solution for urban projects.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now