As urbanization progresses, infrastructure and construction projects are being developed and improved. This leads to a large amount of construction waste. If not dealt with properly, it will take up a lot of land and space, causing pollution and wasting resources.

01 What is Construction Waste Recycling Block Production Line?

Back

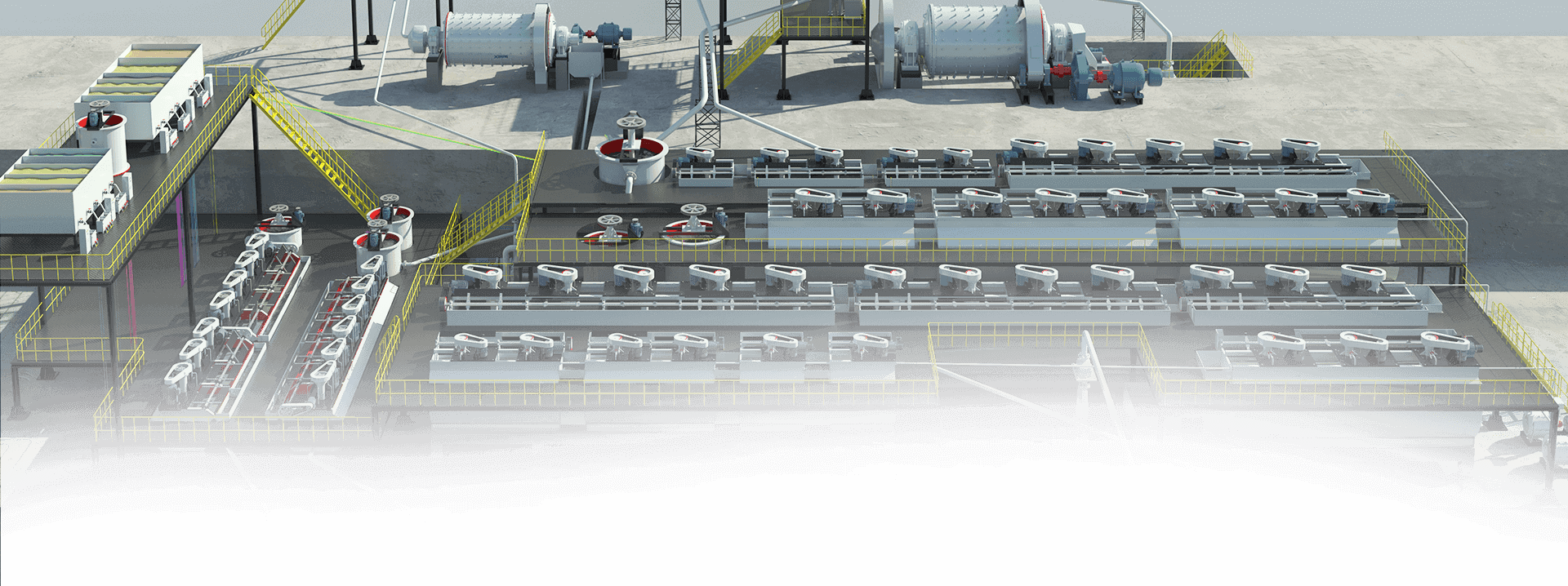

The construction waste block production line is a system that converts demolition and construction debris into usable building blocks. The process typically includes crushing, screening, mixing, molding, and curing, allowing for the production of a variety of concrete products such as hollow blocks, paving bricks, and more. These production lines can be either stationary or mobile, with the primary objective of recycling construction waste, minimizing landfill usage, and producing eco-friendly building materials.

02 How Does the Construction Waste Brick Making Machine Work?

Back

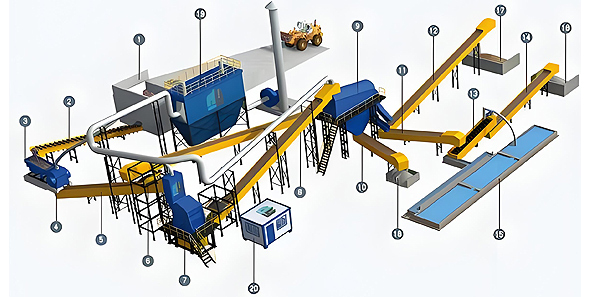

The construction waste brick making machine operates through several key stages:

1. Crushing: The large pieces of construction waste are first broken down into smaller fragments, making them easier to process.

2. Screening: The material is then screened to separate different particle sizes, ensuring suitable raw materials for brick production.

3. Mixing: Construction waste is mixed with appropriate binders and additives to ensure the strength and durability of the final product.

4. Compression Molding: The mixture is compressed into molds to form the initial brick shape.

5. Curing and Maintenance: After molding, the bricks undergo a curing process to ensure they reach the required strength and stability for use in construction.

03 Features and Benefits of the Construction Waste Brick Making Machine

Back

1. Eco-friendly and Energy-efficient

It reduces construction waste, prevents pollution, and minimizes the use of natural resources, offering significant environmental benefits.

2. Efficient Waste Management

The machine processes various construction waste types, such as concrete and brick debris, maximizing recycling and reducing urban waste.

3. Cost Reduction

Bricks made from construction waste lower raw material costs, saving money and minimizing transportation and disposal expenses.

4. Improving Urban Environments

By converting waste into bricks, it reduces landfill pressure and improves the overall environmental quality in cities.

5. Wide Adaptability

It can process diverse construction debris, providing stable performance and adaptability to different waste materials.

04 How to Choose the Right Construction Waste Brick Making Machine?

BackWhen selecting a construction waste brick making machine, consider the following factors:

1. Processing Capacity: Choose a machine that meets the required processing capacity for your needs to ensure efficient production.

2. Quality and Performance: Opt for equipment with stable performance and a long service life to avoid production interruptions caused by equipment failures.

3. Environmental Performance: Ensure the machine complies with environmental standards, minimizing noise and emissions during operation.

4. After-sales Service: Select a manufacturer that provides high-quality after-sales service, ensuring timely installation, training, and maintenance.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com