Mobile concrete mixing station is a kind of movable concrete mixing station equipment. It has the same operational processes, modes of operation, and maintenance requirements as a fixed fully automatic batching plant; meanwhile, it also features unique advantages such as flexible mobility, quick and easy assembly and disassembly, and simple storage management. It is the optimal matching model for mobile construction projects in highways, railways, bridges, ports, and hydropower engineering.

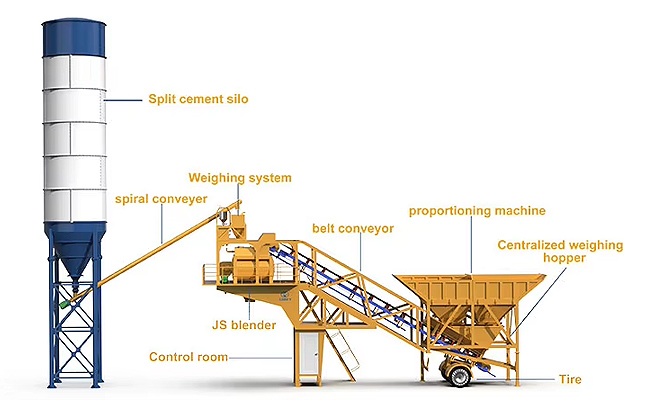

01 Structure of the Mobile Concrete Batching Plant

Back

1. Main Chassis: The main mixing machine chassis is cantilever-shaped and contains the trailer hitch pin for towing trucks and parking support legs. On the chassis are installed the mixer, cement, water, and admixture weighing scales. Surrounding the chassis are inspection walkways and railings.

2. Control Room: The control room is located beneath the main chassis and houses the fully automatic control system of the batching plant, which is the same as that of a fixed batching plant. During operation, the control room acts as the front support point for the entire plant. During transportation, the control room folds and stores within the frame without needing to disconnect any control wiring.

3. Aggregate Batching and Weighing: This system is located at the rear of the plant. The upper part consists of aggregate (sand and stone) storage bins, which can be divided into 2 or 4 compartments, with extension plates to increase storage capacity. Pneumatic sequential gate operation is used, and the aggregate weighing adopts a cumulative method for multiple materials. The bottom is equipped with a walking rear axle and frame support legs for operation.

4. Belt Conveyor Frame: This frame is a truss structure connecting the main chassis and aggregate batching frame, housing the belt conveyor. The main chassis frame, belt conveyor frame, and batching frame form an integrated main structure of the mobile concrete batching plant.

5. External Components: These include the cement silo and screw conveyor. The external components remain assembled as a whole during both operation and transportation, requiring no disassembly and allowing for integrated transport and assembly.

6. Main Mixer: Generally uses a JS-type compulsory mixer, which can quickly and uniformly mix both flowable and dry-hard concrete.

02 Working Principle of the Mobile Concrete Batching Plant

Back

The Mobile Concrete Batching Plant works as follows:

Material Supply: Various materials such as aggregates, sand, stones, cement, and additives are provided through independent storage systems. Each material has its own storage bin.

Automatic Control System: The entire process is controlled by a fully automated control system, which includes software, hardware, monitoring, and operation interfaces.

Batching and Weighing: Materials are automatically batched and weighed according to preset proportions. Each material’s weighing is highly accurate to ensure the concrete quality.

Mixing Process: A compulsory mixer (such as JS-type) is used to mix the materials within a set time to achieve uniformity in the final product.

Transport and Discharge: The mixed concrete is transported via conveyor belts or directly discharged into transport vehicles for delivery or use.

03 Advantages of the Mobile Concrete Batching Plant

Back

1.The computer software operation is simple and clear.

2.It is easy to transport.One towing vehicle is generally sufficient to complete the site conversion work.

3.It occupies a small footprint and can be assembled quickly.

4.Adopts a double horizontal shaft forced mixer, which has strong mixing capacity .

04 Specifications of Mobile Concrete Batching Plant

Back| Parameter | Model | ||||

| YHZS25 | YHZS35 | YHZS50/60 | YHZS75/90 | YHZS100 | |

| Theoretical Productivity (M3/H) | 25 | 35 | 50/60 | 75 | 100 |

| Central Mixer | 0.5m3per batch | 0.75m3per batch | 1.0m3per batch | 1.5m3per batch | 2.0m3per batch |

| Aggregate Batching System | 4 hoppers | 4 hoppers | 4 hoppers | 4 hoppers | 4 hoppers |

| Discharging Height(Mm) | 3800 | 3800 | 3800 | 4000 | 4000 |

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com