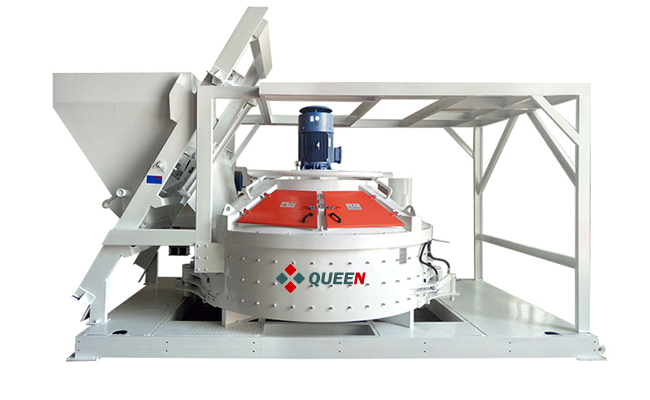

Planetary Concrete Mixer is a high-efficiency, dead-point-free mixing equipment, a versatile mixing machine. The planetary mixer rotates around its own axis while also revolving around the central axis, much like the movement of planets in the universe. It features high efficiency, high quality, and low maintenance. It is suitable for various industries and can mix a wide range of materials.

01

Working Principle of Planetary Concrete Mixer

Back

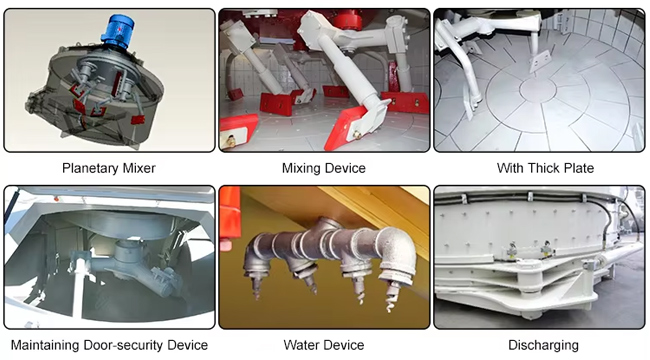

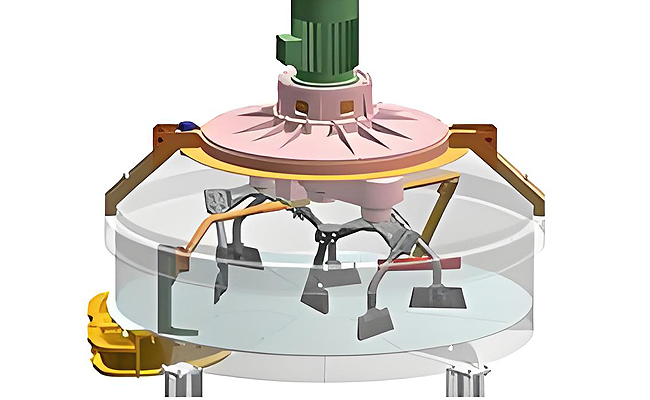

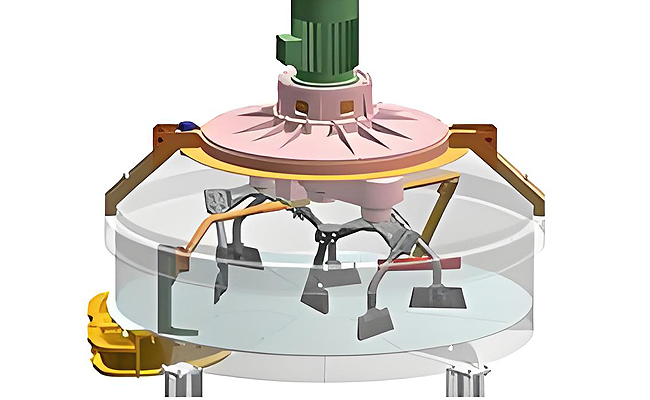

Planetary Concrete Mixer has a unique and novel mixing method, with two or three planetary agitators and one or two automatic scrapers inside the mixing vessel. While the agitators rotate around the vessel’s axis, they also rotate around their own axis at different speeds, causing the materials to undergo complex motion inside the vessel, resulting in strong shear and kneading forces. Additionally, the side scraper rotates around the vessel’s axis, scraping off the material sticking to the wall, ensuring better mixing results.

When the planetary frame rotates, it drives the three agitator shafts inside the vessel to revolve around the material bucket while the agitator shafts rotate at high speed. This results in intense shear and kneading action, achieving full dispersion and mixing. A side scraper attached to the planetary frame continuously wipes the vessel wall, preventing material build-up and improving the mixing effect. The mixing time of the planetary mixer can be adjusted according to the properties of the material, and users can easily control it through the control panel. The operation is simple and fast.

02

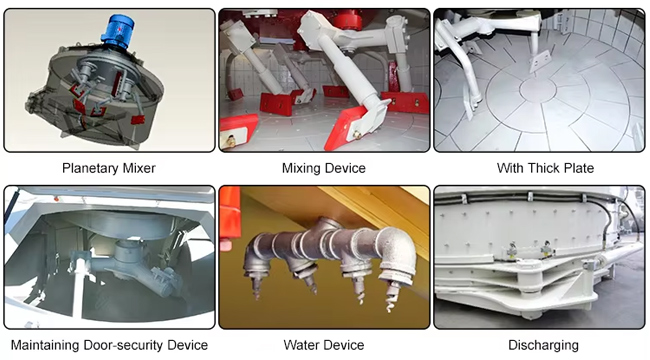

Structure of Planetary Concrete Mixer

Back

03

Specifications of Planetary Concrete Mixer

Back

| Item |

Type |

| MP250 |

MP330 |

MP500 |

MP750 |

MP1000 |

MP1500 |

MP2000 |

MP2500 |

MP3000 |

| Intput capacity(L) |

375 |

500 |

750 |

1125 |

1500 |

2250 |

3000 |

3750 |

4500 |

| Output capacity(L) |

250 |

330 |

500 |

750 |

1000 |

1500 |

2000 |

2500 |

3000 |

| Output capacity(kg) |

600 |

800 |

1200 |

1800 |

2400 |

3600 |

4800 |

6000 |

7200 |

Diameter of mixing

Trough(mm) |

1300 |

1540 |

1900 |

2192 |

2496 |

2796 |

3100 |

3400 |

3400 |

| Mixing power(kw) |

11 |

15 |

18.5 |

30 |

37 |

55 |

75 |

90 |

110 |

| Discharging power(kw) |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

3 |

4 |

4 |

4 |

| Scraper(nr) |

1/2 |

1/2 |

1/2 |

1/3 |

2/4 |

2/4 |

3/6 |

3/6 |

3/9 |

| Paddle |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

Discharging

paddle |

– |

– |

– |

1 |

1 |

1 |

2 |

2 |

2 |

| Weight(kg) |

1200 |

1700 |

2000 |

3500 |

6000 |

7000 |

8500 |

10500 |

11000 |

mm Dimension

(L*W*H) |

1570

x1480

x1750 |

1862

x1850

x1855 |

2220

x2071

x1880 |

2550

x2295

x2195 |

2893

x2606

x2217 |

3223

x2906

x2425 |

3625

x3235

x2630 |

3893

x3555

x2695 |

3893

x3555

x2975 |

| Lifting power(kw) |

3 |

4 |

4 |

7.5 |

11 |

15 |

18.5 |

– |

– |

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com