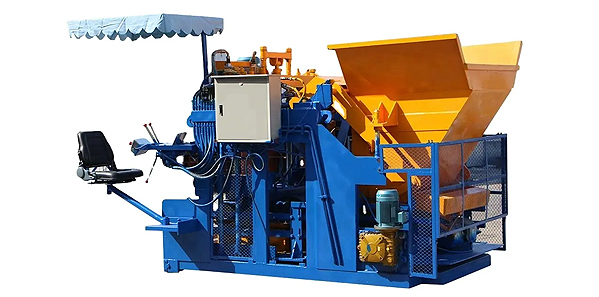

QMY10-15 Mobile Egg Laying Block Machine can produce hollow, solid, paving, curbstone, and interlocking blocks. Brick size and mold shape can be customized to meet various construction needs.

No pallets required—blocks are formed directly on the ground, saving cost and space. High efficiency, easy operation, and durable design make it ideal for large-scale projects.

01 Features of QMY10-15 Mobile Egg Laying Block Machine

Back1) New design, simple structure, easy in installation and operation.

2) Adopt Japan Omron and France Schneider brand switches, Siemens and ABB brand motors to make high quality machinery.

3) High vibration ensure high density of the finished products, suitable for solid bricks and pavers.

4) Reasonable raw material ratio can produce high strength standard brick, after forming, can stack immediately.

5)No need pllates,reduces investments.

02 Preparatory work before the operation

BackCheck all moving parts for abnormalities, and inspect the lubrication of components, the tightness of fastening screws, and the lubrication at various refueling points.

Check the power supply: Voltage should be 380V ±10%. Turn on the power switch and check for any missing phase.

Check the hydraulic oil level: The hydraulic oil should be filled to about 4 cm below the fuel filler opening. The manual valve handle should be in the middle position (this is the unloading state).

Check the motor oil pump’s rotation direction: Ensure it is turning in the correct direction. If reversed, there will be no oil pressure.

Adjust the system pressure: Start the oil pump motor. Push the valve handle downward to the fuel tank position, open the pressure gauge switch, and adjust the regulator valve handle. (To adjust the pressure, turn the regulator valve handle—clockwise to increase pressure, counterclockwise to decrease.) Set the system pressure to 10–16 MPa and tighten the locknut. (Note: The pressure is preset before leaving the factory.)

System unloading: The valve handle should be in the middle position. The pressure gauge should read around 0–1 MPa during normal unloading. (This is pre-adjusted at the factory.)

Test the valve operation: Toggle the valve handle and observe whether the fuel tank is operating properly. Check if the mold is correctly pressed and the mold core is in the right position. If all functions are normal, the machine is ready for production.

03 Material Proporation of QMY10-15 Egg Laying Block Machine

BackAccording to local market condition, we can design a proper proportion of raw material.Common raw material: Fly ash, cement, sand, crash stone, additive, constrution garbage etc.

1. 8-10% cement, 30-40% sand , 50-60% crushed stone.

2.8-10% cement, 30% flyash, 60% sand or stone powder

04 Specifications of QMY10-15 Mobile Block Machine

Back| Overall Dimension | 3150*1800*2400mm |

| Voltage | adapt to local voltage |

| Demold method | hydraulic |

| Cycle Time | 10-15 seconds |

| Motors Power | 16kw |

| Weight | 4200 kg |

05 Production Capacity of QMY10-15 movable block machine

Back| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block | 400x200x200 | 10-15 | 10 | 1800-2100 | 14400-16800 | |

| Hollow block | 400x150x200 | 10-15 | 14 | 2520-2940 | 20160-23520 |

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com