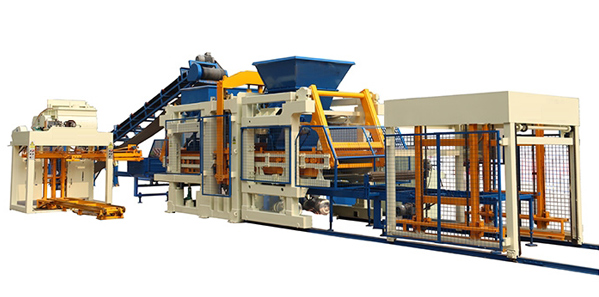

QT10-15 Block Making Machine offers high output and a wide variety of concrete products. The secondary distribution mechanism allows for the production of colored paving bricks. It can be designed with a higher frame to meet customer needs, with the capability to produce bricks up to 400mm in height, ensuring more stable and reliable performance. It is suitable for large and medium-sized enterprises, supporting both semi-automatic and fully automatic production lines. With a high degree of automation, it maximizes production efficiency and output.

01 Technical Specifications of QT10-15

Back| Overall Dimension | 9350x2520x2950mm |

| Rated pressure | 21MPa |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Pallet Size | 1150x900mm |

| Motors Power | 63.5kw |

| Weight | 11000kg |

02 Advantages of QT10-15 Block Making Machine

Back| ENLARGE THE VIBRATING BOX The vibrating source is uniform and stronger. |

|

|

SIEMENS PLC International brand, long service life, basically not damaged. |

| 4 SIEMENS VIBRATION MOTORS fast start, high frequency, strong vibration force, make good brick quality. |

|

|

SCHNEIDER, OMRON ELECTRICAL DEVICES Interval pressure supply, each action is fast and smooth. |

| JAPAN YUKEN HYDRAULIC VALVE / PROPORTIONAL VALVE Fast response, long life.. |

|

|

MATERIAL FEEDER V-shaped feeding tooth, uniform feeding, 0 failure rate. |

| MATERIAL HOPPER Adopt endless belt, uniform, more accurate discharge volume. |

|

|

GUARD NET Ensure the safety of workers, good-looking appearance. |

03 QT10-15 Production Capacity

Back| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block | 400x200x200 | 15-20 | 10 | 1800-2400 | 14400-19200 | |

| Hollow block | 400x150x200 | 15-20 | 14 | 2520-3360 |

20160-26880 |

|

| Solid block | 240x110x70 | 15-17 | 40 | 8470-9600 |

67760-76800 |

|

| Paver | 225×112.5×60 | 15-25 | 16 | 3456-5760 |

27648-46080 |

|

| Paver | 200x100x60 | 15-25 | 40 | 5760-9600 |

46080-76800 |

04 Why Choose the QT10-15 Block and Brick Machine?

Back✅ High Production Efficiency: Designed for large working platforms, output is about 20% higher than similar models. Capable of producing large hydraulic slope protection blocks, curbstones, and more.

✅ High-Quality Products: The machine delivers dense, strong, and precisely sized bricks, suitable for colored pavement bricks, grass-planting bricks, eco-bricks, etc.

✅ Advanced Technology: Features four-shaft synchronized vibration, Schneider frequency control system, and touchscreen operation. Key components use international brands like Fuji and Siemens for stability and reliability.

✅ Strong Versatility: Supports a wide range of brick types and can produce various sizes by changing molds, meeting diverse construction and landscaping needs.

✅Energy Saving & Eco-Friendly: Uses hydraulic motor-driven vibration to reduce motor heating. Produces colored tiles without clay, saving energy and reducing raw material costs and environmental impact.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com