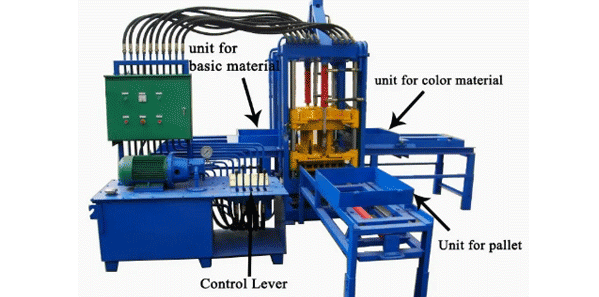

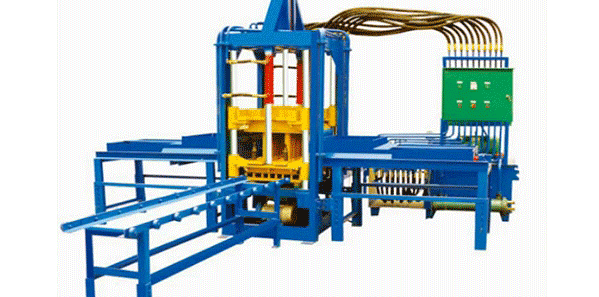

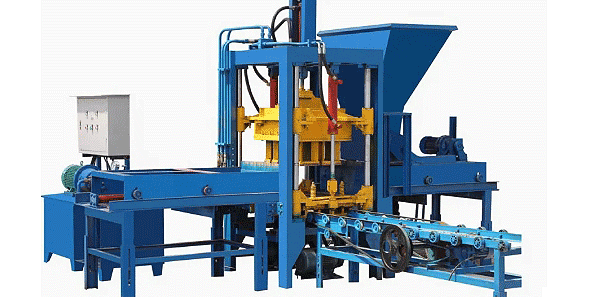

QT3-20 Paver Block Machine is an efficient and fully automatic hydraulic brick making machine, mainly used to produce various standard bricks, concrete blocks, porous blocks, paving bricks etc. The equipment adopts advanced hydraulic transmission and PLC intelligent control system, with the characteristics of high production efficiency, good molding quality and easy operation. It is suitable for small and medium-sized brick factories, construction sites and environmentally friendly building materials production enterprises.

01 Advantages of QT3-20 Paver Block Machine

Back(1) High efficiency and energy saving

Adopt hydraulic + vibration dual forming technology to ensure high density of brick blanks and reduce scrap rate.

Equipped with variable frequency energy-saving motor to reduce energy consumption, saving more than 30% of electricity compared with traditional brick machines.

(2) Intelligent control

PLC + touch screen control system, which can adjust parameters such as pressure, vibration frequency, and forming time, and is easy to operate.

Equipped with fault self-detection function to reduce downtime and maintenance time.

(3) Strong adaptability

Different molds can be replaced to produce bricks of various specifications (such as standard bricks, hollow bricks, curbstones, etc.).

Applicable to various raw materials such as cement, fly ash, slag, recycled aggregates from construction waste, etc.

(4) Stable and durable

Key components are made of high-strength steel and imported hydraulic components to ensure long-term stable operation.

The vibration table adopts shock-absorbing design to reduce noise and extend equipment life.

02 How Does QT3-20 Paver Block Machine Work?

BackFeeding: The mixed concrete raw materials are fed into the hopper.

Material distribution: The automatic material distribution system evenly fills the mold.

Vibration and pressurization: High-frequency vibration + hydraulic pressing to form the bricks.

Demolding: The hydraulic ejector pushes the bricks out of the mold.

Brick discharge: The bricks are sent to the curing area or stacker by the conveyor belt.

03 Specifications of QT3-20 Block Machine

BackMain Technical Parameters

| Overall Dimensions |

2800×1160×2690mm |

| Rated Pressure |

16Mpa |

| Vibration Type |

Table Vibration |

| Vibration Frequency |

3800-4200 times/min |

| Pallet Size |

680×535mm |

| Molding Cycle |

15-20 seconds |

| Power |

17kW |

Number of Blocks / Bricks per Pallet

|

Brick Size (mm) |

Quantity (blocks/pallet) | Illustration |

| 240x115x53 |

20 |

|

| 200x100x60 |

10 |

|

| 225×112.5×60 | 10 |  |

04 What Can QT3-20 Be Used For?

BackConstruction Industry: Produces solid blocks and hollow bricks for building construction.

Municipal Engineering: Manufactures curb stones and permeable paving bricks for urban road construction.

Environmental Protection: Utilizes construction waste, fly ash, and other recycled materials for brick production.

Agricultural Water Conservancy: Produces slope protection bricks for river channels and farmland water conservancy projects.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com