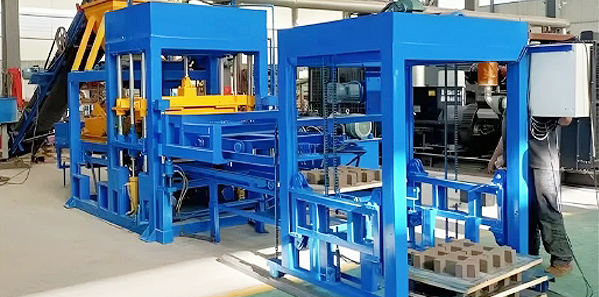

01 Technical Specifications of QT5-15 Hollow Block Machine

Back| Overall Dimension | 5120x1950x2810mm |

| Rated pressure | 16MPa |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Pallet Size | 1100x550mm |

| Motors Power | 26.5kw |

| Weight | 5500kg |

02 Advantages of QT5-15 Hollow Block Machine

Back| ENLARGE THE VIBRATING BOX The vibrating source is uniform and stronger. |

|

|

SIEMENS PLC International brand, long service life, basically not damaged. |

| SIEMENS MOTOR Strong power and long service life. |

|

|

SCHNEIDER, OMRON ELECTRICAL DEVICES Interval pressure supply, each action is fast and smooth. |

| JAPAN YUKEN HYDRAULIC VALVE / PROPORTIONAL VALVE Fast response, long life.. |

|

|

GUARD NET Ensure the safety of workers, good-looking appearance. |

| MATERIAL FEEDER 360° feeding tooth, fast speed and easy to repair. |

|

03 Productivity of QT5-15

Back| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block |  |

400x200x200 | 15-20 | 5 | 900-1200 | 7200-9600 |

| Hollow block |  |

400x150x200 | 15-20 | 7 | 1260-1680 | 10080-13440 |

| Solid block |  |

240x110x70 | 15-17 | 26 | 4680-6240 | 37440-49920 |

| Paver |  |

225×112.5×60 | 15-25 | 16 | 2330-2880 | 18400-23040 |

| Paver |  |

200x100x60 | 15-25 | 20 | 2800-2600 | 23040-28800 |

04 Features of QT5-15 Hollow Block Machine

Back

User-friendly operation with stable output quality

Multi-functional molds for various brick types (including non-fired bricks)

High output: 5,000–15,000 bricks/day (depending on block type)

Low maintenance with robust steel structure & heat-treated molds

05 Why Choose the QT5-15 Hollow Block Machine?

Back✅ High Production Efficiency – Save Time & Labor

Fast cycle time: 11-25 seconds per block

Independent feeding control: Reduction motor-driven hopper boosts efficiency

Automated operation reduces manual handling

✅ Superior Quality & Stable Performance

Bow-beam demolding system ensures smooth, synchronized mold release

Dual vibration system (2,800-4,500 vibrations/minute) for perfect compaction

Heat-treated molds guarantee long-term dimensional accuracy

✅ Cost-Effective Operation

Low power consumption: Total 41kW (optimized energy use)

Minimal material waste: Precision vibration reduces raw material loss

Durable construction: Heavy-duty steel frame extends machine life

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com