The semi-automatic block production line offers an ideal balance between efficiency and affordability. Designed for medium-scale operations, it combines automated processes with manual handling to ensure stable production while maintaining flexibility. Aggregates and cement are precisely measured and mixed before being delivered to the block making machine. The finished blocks are automatically stacked and manually transferred to the curing area using a forklift.

With a simplified structure and user-friendly controls, this line reduces equipment investment and maintenance costs, making it a smart choice for startups or regional construction projects. It supports the production of a wide range of concrete products, including hollow blocks, solid bricks, paving stones, and curbstones.

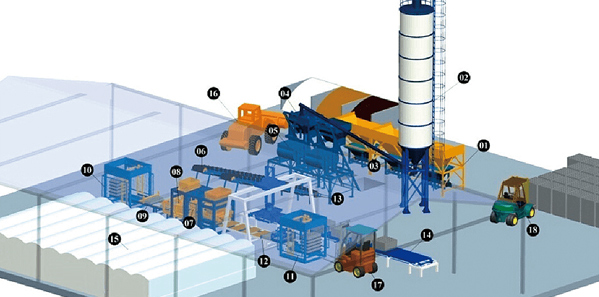

01 Semi-automatic Block Production Line Components

Back

| Semi Automatic Concrete Block Production Line | ||

| 1 Automatic Batching Station | 2 Cement Silo | 3 Screw Conveyor |

| 4 Cement Scale | 5 Compulsory Mixer | 6 Belt Conveyor |

| 7 Concrete Block Machine | 8 Face Mix Section | 9 Blocks Conveying System |

| 10 Stacker | 11 Un-stacker | 12 Pallet Conveying System |

| 13 Automatic Cuber | 14 Exit Conveyor | 15 Curing Chamber |

| 16 Wheel Loader | 17 Fork Lift | 18 Fork Clamp |

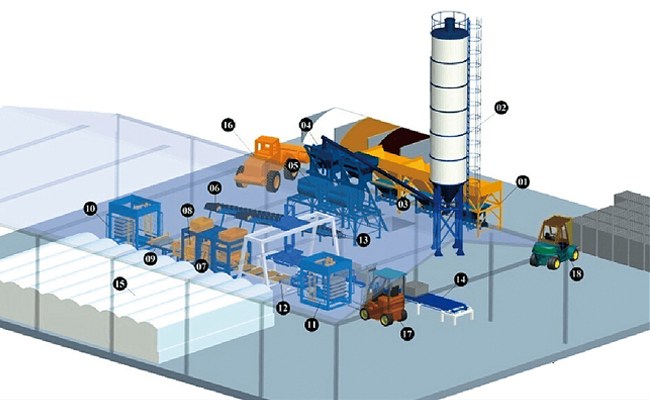

02 Process Flow of the Semi-automatic Block Production Line

BackThe wheel loader first loads various aggregates into the batching station, where they are weighed according to the required proportions and then mixed with cement from the silo. The blended materials are fed into the mixer. Once evenly mixed, the materials are delivered via belt conveyor to the block making machine. The freshly molded blocks are then transferred to the automatic stacker. After stacking, a forklift transports the pallets of blocks into the curing chamber. Once curing is complete, a pallet tumbler separates the pallets one by one. Finally, the automatic cuber stacks the blocks into piles, and the forklift with a clamp attachment transports the finished products to the storage yard for sale.

03 Key Features of the Semi-automatic Block Production Line

Back1. The semi-automatic production line equipped with QT series block making machine.

2. Aggregate, fine material can be measured, conveyed, lifted automatically. Instant and accurate in batching, guarantee the matching and quality, and improve the quality of product.

3. It is a semi-automatic production line, some operation stages are manual operation such as nature maintenance.

4. Compared with full-automatic production line, the semi-automatic production, simpler in production, lower requirement on worker technical skill, less production cost and energy consumption. Due to nature maintenance, influenced by climatic conditions, output is relatively lower than full-automatic one.

5. Production Capacity depends on the main machine the line adopt.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com