The simple automatic block production line is designed for the production of high-strength, high-quality concrete blocks, special permeable bricks for sponge cities, high value-added imitation stone PC bricks, municipal pavement bricks, curb stones, slope embankment bricks, and various other concrete products. By adjusting the mix design, it can also produce these products using recycled solid waste materials such as construction debris, furnace slag, and fly ash.

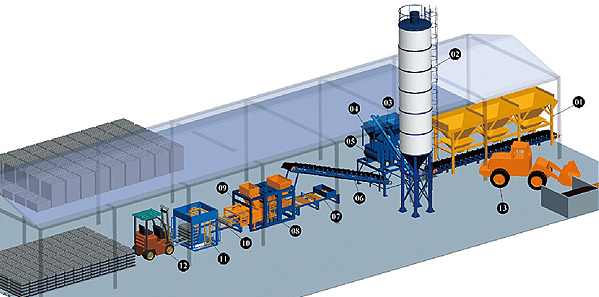

01 Simple Automatic Concrete Block Production Line Components

Back

| Simple Automatic Concrete Block Production Line Components | ||

| 1 Automatic Batching Station | 2 Cement Silo | 3 Screw Conveyor |

| 4 Cement Scale | 5 Compulsory Mixer | 6 Belt Conveyor |

| 7 Pallet Conveying System | 8 Concrete Block Machine | 9 Face Mix Section |

| 10 Blocks Conveying System | 11 Automatic Stacker | 12 Fork Lift |

| 13 Wheel Loader | ||

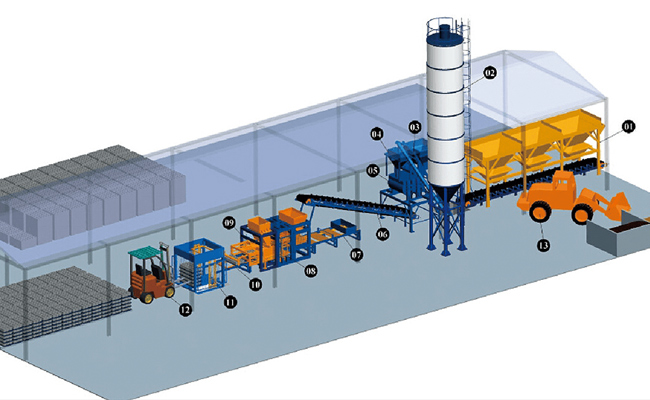

02 Process Flow of the Automatic Block Production Line

BackAggregates are first loaded into the batching plant, where they are accurately weighed and combined with cement from the silo. The mixed materials are then delivered to the mixer for thorough blending. Once evenly mixed, the concrete is conveyed by a belt conveyor to the block making machine. After forming, the blocks are cleaned by the block sweeper and transferred to the stacker. Finally, a forklift or two workers can move the finished blocks to the yard for natural curing.

03 Advantages of the Automatic Block Production Line

BackCompact and Rational Layout: Requires minimal floor space with a well-organized structure, making it suitable for smaller workshops.

High Adaptability and Scalability: Compatible with both high and low-level block collecting lines; easily upgradable to a more automated production line.

High Reliability and Flexibility: Simple and stable system with a modular design that allows customization to meet specific product requirements.

Cost-Effective and Practical: Low investment with high returns.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com