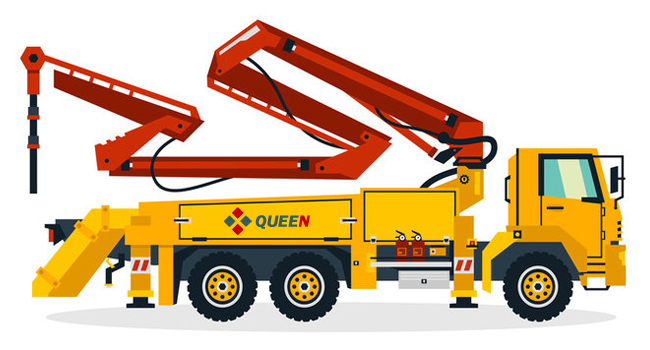

The Truck-Mounted Concrete Boom Pump is a highly efficient and specialized piece of construction equipment designed for concrete transportation and pouring. It offers advantages such as reduced construction time, a wide coverage area, low labor intensity, and the ability to operate in confined spaces.

01 Components of the Truck-mounted Concrete Boom Pump

BackThe overall structure of the concrete pump truck includes several key components, such as the chassis, boom system, turret, hydraulic system, electrical system, and pumping system. These components work together to ensure the smooth operation and efficient concrete pouring of the pump truck.

02 Working Principle of the Truck-mounted Concrete Boom Pump

BackAfter the concrete mixer truck unloads the material into the pump truck’s hopper, the pumping system is activated to press the concrete into the delivery pipe, which is then discharged through the end hose. The boom system is responsible for accurately delivering the concrete to the designated location.

03 Specifications of our Concrete Boom Pump

Back| Model | QM5028 | QM5030 | QM5033 | QM5037 | QM5042 | QM5047 | QM5056 | QM5063 |

| Maximum Vertical Height Of Boom (M) | 27.4 | 29.2 | 32.5 | 36.6 | 41.8 | 46.9 | 56 | 61.5 |

| Horizontal Distribution Radius Of Boom (M) | 23.8 | 25.6 | 29 | 32.6 | 38 | 42.7 | 52 | 57.5 |

| Chassis Brand | FOTON / SHACMAN / SINOTRUCK / FAW/ISUZU / DFAC | |||||||

| More Detailed Information, Please Contact Us. | ||||||||

04 What Factors Affect the Price of Concrete Pump Trucks?

BackBoom Length: The longer the boom length of the concrete pump truck, the higher the price. The boom length directly impacts the working range of the pump truck. A longer boom may lead to waste, while a shorter one might not be able to deliver concrete to the designated construction site. Therefore, within your budget, it’s recommended to choose a truck with a longer boom if possible.

Brand: The price varies depending on the brand. The size of the company, its strength, and personnel configuration can all influence the price of the concrete pump truck.

Chassis and Boom Selection: The choice of chassis and boom, along with the use of different key components, directly affects the price. If the technology is advanced and reliable, the price will naturally be higher; conversely, a less advanced pump truck will likely be less expensive.

05 Concrete Pump Truck Maintenance Knowledge You Should Know

Back

1. Regularly inspect the rotating turret, boom, and outriggers for any cracks in the welds.

2. Use original factory-specification pipes for the pump. Many external pipes are made from substandard materials, and to improve their abrasion resistance, their wall thickness is increased. This results in heavier pipes for the same length, which can reduce the lifespan of the boom. Therefore, always use original pump pipes. Also, make sure to clean the entire truck after each pumping job.

3. Regularly lubricate the lubrication points on the boom to ensure optimal performance. The boom’s pins and shafts should be lubricated 1 to 2 times a month. Each grease point must be properly lubricated, and old grease should be pushed out and cleaned. If necessary, open the boom to ensure proper lubrication of all pin shafts.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com