What Are the Raw Materials for a Brick Making Machine?

queenbrick

queenbrick

June 4, 2025

June 4, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Brick making machines can utilize a wide range of raw materials, such as, clay, shale, coal gangue (coal refuse stone), fly ash, slag, industrial waste (e.g., metallurgical slag), domestic garbage, river sludge, Other natural and industrial by-products

01Why Raw Material Processing Matters

BackTo be suitable for brick production, these raw materials must go through several processing steps to achieve the required technical properties:

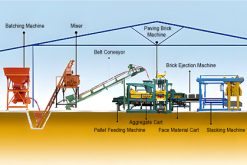

Crushing ⇒ Stirring ⇒ Blending ⇒ Aging ⇒ Milling ⇒ Modifying or enhancing material properties

Proper processing ensures the materials meet production needs — especially when making hollow bricks, which are more fragile due to thinner walls and internal cavities.

02Special Requirements for Hollow Bricks

BackHollow brick production demands:

1. Stricter control of the raw material mix

2. Fewer harmful impurities

3. Better particle size distribution (gradation)

4. Even mineral dispersion

5. Improved plasticity and bonding strength

03Basic Requirements for Raw Materials

BackTo ensure stable and high-quality brick production, raw materials should meet standards in:

1. Chemical Composition

Must promote good bonding and firing characteristics.

2. Mineral Composition

Should be uniform and suitable for high-temperature firing.

3. Physical Properties

Must offer good plasticity, strength, and workability.

04Conclusion

BackChoosing the right raw materials — and processing them properly — is key to producing durable, high-performance bricks. Whether you’re making solid bricks or hollow blocks, consistency in raw material quality directly impacts structural strength and cost efficiency.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now