Electric vs Diesel: Which Concrete Mixer Pump is Right for You?

queenbrick

queenbrick

October 30, 2025

October 30, 2025

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Concrete mixer pumps are essential equipment in the construction industry, enabling the efficient mixing and pumping of concrete to various locations. When it comes to selecting the right mixer pump for your project, one of the most important decisions is whether to choose an electric or diesel-powered model. Both types have their advantages and drawbacks, making it crucial to evaluate your specific needs before making a choice. In this article, we’ll break down the key factors you should consider to help you make the best decision.

01What is a Concrete Mixer Pump?

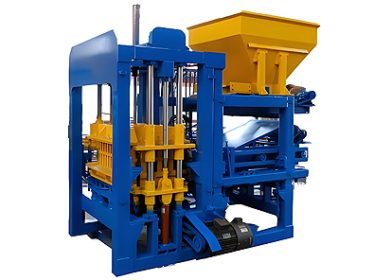

BackA concrete mixer pump combines mixing and pumping functions into one machine, ideal for projects that require concrete to be mixed and pumped over distances. These pumps mix the materials (cement, sand, aggregates, water) and then pump the mixture to the desired location, making them essential for high-rise buildings, roads, and large foundations.

02Advantages and Disadvantages of Electric Concrete Mixer Pumps

BackAdvantages:

1. Eco-friendly: Electric pumps produce zero emissions.

2. Lower Operating Costs: Cheaper electricity and minimal maintenance costs.

3. Quieter: Ideal for residential or urban construction sites.

Disadvantages:

1. Dependence on Power: Requires a reliable power supply, limiting use on remote sites.

2. Lower Power Output: Not suitable for large, heavy-duty projects.

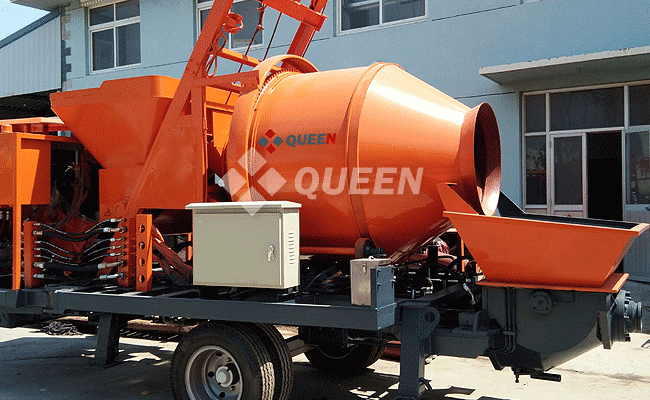

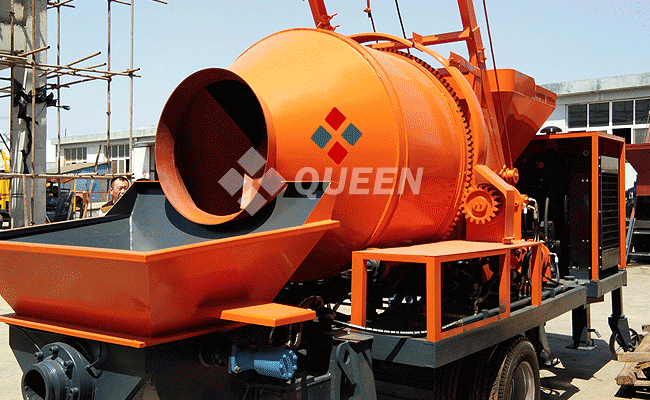

03Advantages and Disadvantages of Diesel Concrete Mixer Pumps

BackAdvantages:

1. High Power: Ideal for large-scale and demanding projects.

2. No External Power Needed: Suitable for remote areas.

3. Durability: Built to handle rugged conditions.

Disadvantages:

1. Higher Operating Costs: Diesel fuel and maintenance are more expensive.

2. Environmental Impact: Produces emissions and is noisier.

04How to Choose the Right Concrete Mixer Pump

Back1. Project Size: Electric pumps are great for smaller to medium projects, while diesel pumps excel in large-scale operations.

2. Location: Choose electric pumps if power is readily available; diesel is best for remote areas without reliable electricity.

3. Budget and Maintenance: Electric pumps have a lower upfront cost and minimal maintenance, but diesel pumps may offer better performance for demanding tasks.

05Conclusion: Make the Best Choice for Your Project

BackThe choice between electric and diesel concrete mixer pumps depends on your specific project needs. Electric pumps are better for eco-friendly, cost-effective solutions in urban areas, while diesel pumps are more suitable for high-powered, remote, or large-scale projects. Evaluate the scale, location, budget, and environmental concerns to make the most informed decision.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com

Message

Message Chat Now

Chat Now