This Fully Automatic Block Production Line is independently developed and manufactured by Queen Machinery, integrating numerous proprietary core technologies. The overall design is well-structured with a smooth production flow. Years of market application have proven that the equipment is well-configured and operates reliably.

The production line is suitable for manufacturing a variety of high-strength, high-quality ordinary concrete blocks, permeable bricks for sponge cities, high value-added imitation stone PC bricks, and municipal curb stones. Industrial wastes such as slag and fly ash are used as substitutes for conventional sand and gravel to produce these products.

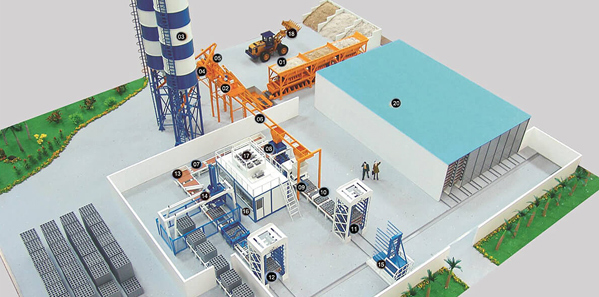

01 Fully Automatic Block Production Line Components

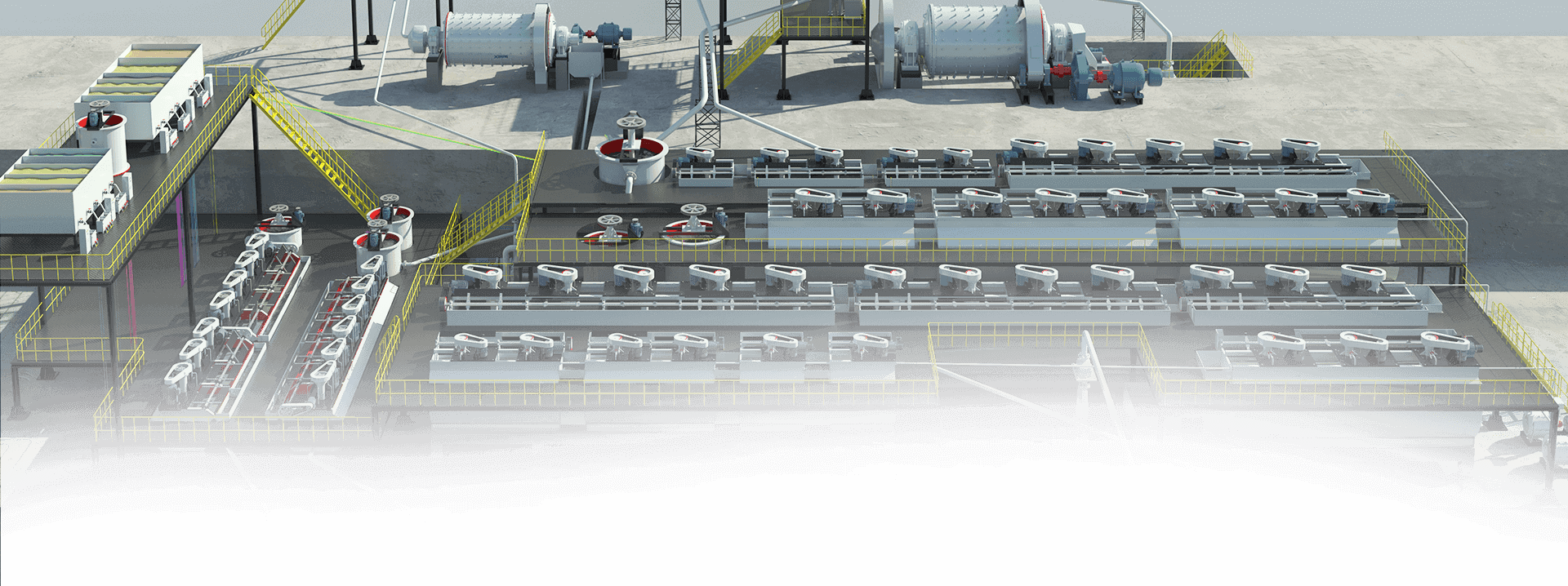

BackKey components of the production line include the batching system, mixing system, automatic block making machine, automatic elevator (lowerator), automatic shuttle car, block curing system, automatic stacking system, automatic packaging system, automated conveying circulation system, and central control system.

| Full Automatic Concrete Block Production Line | ||

| 1 Automatic Batching Station | 2 Compulsory Mixer | 3 Cement Silo |

| 4 Screw Conveyor | 5 Cement Scale | 6 Belt Conveyor |

| 7 Pallets Conveying System | 8 Concrete Block Machine | 9 Blocks Conveying System |

| 10 Block Sweeper | 11 Elevator | 12 Lowerator |

| 13 Pallet Tumbler | 14 Automatic Gantry Type Cuber | 15 Finger Car System |

| 16 Central Control Room | 17 Hydraulic Station | 18 Wheel Loader |

| 19 Fork lift | 20 Curing Chamber | |

02 Process Flow of the Fully Automatic Block Production Line

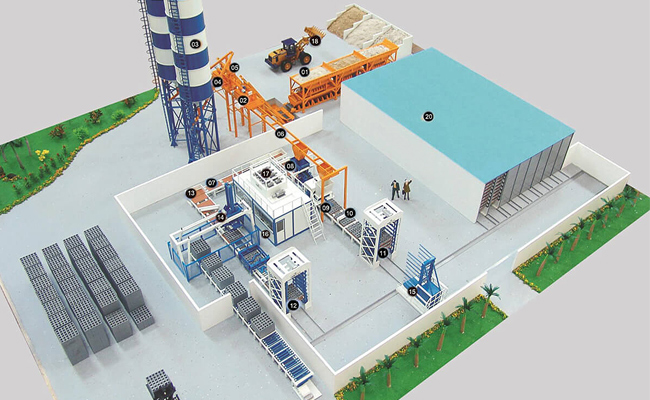

BackThe entire production process is computer-controlled and mechanically automated. It starts with sensors measuring the moisture content of raw materials, followed by intelligent dynamic adjustment and mixing of moisture levels. The wet material is then conveyed to the molding stage for shaping and production control. After molding, wet bricks are transported and lifted via an elevator system for stacking. An automatic finger car transfers the stacked products to the curing kiln, where it recognizes empty kilns and their numbers to load the wet products for curing. Once cured, the dry products are moved to the lowerator, which places them layer by layer onto the dry product conveyor. These are then transferred to the palletizing area, where an automatic gripper stacks the bricks—typically one cubic meter per stack—onto pallets. Finally, the pallets are transported by a platform lorry to the automatic packaging area.

03 Advantages of the Fully Automatic Block Production Line

Back1. The layout is compact and efficient, occupying a reasonable footprint; the line is fully equipped to enable automated production.

2. Advanced technology ensures high performance, stability, and reliability.

3. Modular design provides excellent flexibility, allowing customized product solutions to meet individual customer requirements.

4. The advanced curing kiln optimizes space for curing wet products, prevents damage between pallets and the upper surfaces of blocks, and increases air exposure for improved curing results, leading to higher-quality bricks.

5. High automation includes automatic measuring, mixing, conveying, transferring, storage, sorting, and stacking, greatly reducing labor costs and increasing efficiency.

04 Features of our Fully Automatic Block Production Line

Back1. Rapid Production: The machine boasts a short molding cycle, ensuring high production efficiency.

2. Superior Compaction: Equipped with a specialized high-efficiency vibrator, the machine delivers powerful vibration and exceptional product compaction.

3. Versatility: The machine’s large molding area allows for the production of a diverse range of cement products, catering to various needs.

4. Automation: Fully automated, the machine eliminates manual feeding, reducing labor requirements.

5. Effective Molding: The machine utilizes vertical vibration of the worktable and combined vibration and pressure from the press head, resulting in optimal molding.

6. Cost-Efficient Maintenance: The assembled mold box design facilitates easy replacement of wear parts, minimizing mold maintenance costs.

7. Material Versatility: The machine’s unique arch-breaking device is compatible with a wide range of materials.

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com