According to the aggregate feeding method, the stationary concrete batching plant can be categorized into two types : belt conveyer type and skip hoist type, with production capacities ranging from 25m³/h to 180m³/h.

The belt conveyer concrete batching plant is a high-output plant, where aggregates are fed into the mixer using a belt conveyor. The skip hoist concrete batching plant is suitable for medium and small-sized concrete projects, where aggregates are fed into the mixer using a skip hoist system.

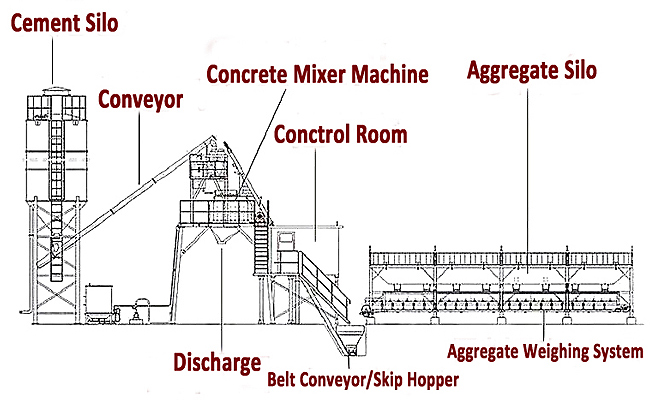

01 Components of the Stationary Concrete Batching Plant

Back

1.Mixing System:Twin-shaft compulsory mixer2.Storage System:Cement silos,aggregate bins

3.Conveying System:Belt conveyors or hoppers

4.weighing System:High-precision cement,water,and additive scales

5.Control System:Fully automatic computer control system

02 Skip hoist concrete batching plant VS belt conveyor concrete batching plant

Back| Item | Skip hoist type | Belt conveyor type |

| Aggregate loading method | Skip hoist | Belt conveyor |

| Aggregate batcher | Accumulative weighing type | Independent weighing type |

| Transitional hopper | Not including | including |

| Packing exterior | Not including | including |

| land needed | smaller | bigger |

| Budget | low | high |

03 Specifications of Stationary Concrete Batching Plant

Back| Technical data | Model | ||||||

| HZS60 | HZN60 | HZS90 | HZN90 | HZS120 | HZS180(150) | HZS240(200) | |

| Theoretical capacity(m³/h) | 60 | 60 | 90 | 90 | 120 | 180(150) | 240(200) |

| Mixer model | JS1000 | MP1000 | JS1500 | MP1500 | JS2000 | JS3000 | JS4000 |

| Batching system | PLD1600 | PLD1800 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Discharging height (mm) | 4100 | 4840 | 4100 | 4100 | 4100 | 4100 | 4100 |

| Maximum aggregates size(mm) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) |

| automatic Cycle time(s) | 60 | 60 | 60 | 60 | 60 | 60(72) | 60(72) |

| Weighing Precision of Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Weighing Precision of Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Additive | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Total power(KW) | 106 | 114 | 145 | 145 | 175 | 215 | 295 |

+86 19137934740

+86 19137934740 queenmachinery@gmail.com

queenmachinery@gmail.com